System Validation leaves paper behind, projecting us into the digital era.

Why some companies keep validating with paper and continuing the burden of it?

Probably some companies still validate using paper because it is habitual and familiar. Although it is more practical at first, as the years go by and the number of validations (one per system and/or equipment) increases, it starts causing certain issues that are important to point out:- Validations are expensive, since they are time-consuming and laborious

- Knowledgeable professionals are scarce

- Companies do not have enough workforce to keep validation schedules up-to-date and must validate new systems which are under implementation

- Stakeholders realize that there are no experts who exist to validate certain systems

- A validation team usually consists of pharmacists, who regularly have to confront technical issues, e.g., database management, automation, and IT

- Over the years, uncontrolled changes eventually may make the paper no longer reflect the reality of the company and its processes, i.e., changes are constant

- • Manual validation process is also very tedious

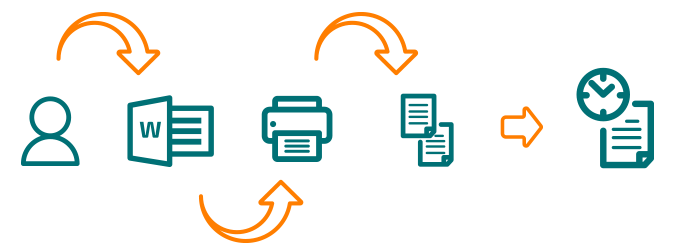

Generally, validation projects are conducted with templates created in Microsoft Word and printed on paper. However, with the increased amount of information generated in a project, the process becomes bureaucratic and laborious. The time it takes to record evidence, prepare folders, print documents, and collect signatures of analysts and stakeholders, may prove that it is necessary to update the whole process at the end.

Physical documents are 'unique children'. There are no copies. In case of losses, it brings to light serious issues to the team who manages the validation. Since they are unique, the signature collection workflow depends solely, and exclusively, on a team member signing off so that the next person in line can do so. This process is usually time-consuming and requires the management of physical documents.

Over time, eventually uncontrolled changes may make validation on paper obsolete, no longer reflecting the reality of the company and its processes

Keeping traceability manually on paper throughout the system lifecycle is a large challenge. When there is a change, an additional difficulty is to track the impact of these changes on the validation deliverables. This increases when we respond to audits. And a question may arise: ‘how to manage role changes successfully and efficiently?’

We’ve found that paper-based validations and qualifications require human resources that spend almost half of their time on activities with low-added value (e.g., formatting documents and organizing folders). And in case there are mistakes, it may cause many more issues that we have to deal with, such as:

- Review and approve workflows, signature collection and management of dates

- Test evidence organization and collection, maintaining integrity and consistency of dates. Tests must be correctly identified and correlated to the step in which the evidence belongs to, attached to the correct step, signed off and dated

- Cancellation of unused fields according to each specific company’s procedures, including signatures and dates

- Manage physical locations of folders and their conditions for auditing presentations.

- CDS (Chromatography Data Software) validation generates on average 600 pages of documents.

- ERP validation generates on average 2,500 pages of documents.

In summary, the traditional paper-based validation format is expensive, outdated, inefficient, and it limits business development. Day by day, this model is becoming unsustainable, bringing risks to compliance.

So, to have a paperless process, is it just necessary to use an EDMS (Electronic Document Management Software)? No!

The EDMS system has become popular in the last decade. It is an interesting system that should be used to manage GMP regulations (Good Manufacturing Practices) documents such as SOPs (Standard Operating Procedures) and other quality documents that have their life cycles controlled by this type of system, from start to finish (creation, revision, approval, and used to its discontinuation). However, this type of system was not intended for validations, nor designed to reduce the time involved for this type of activity. Ideally, what is desired is to have a platform that truly, automatically, and electronically manages the cycles of the validation processes, which is not limited to preparing and approving documents.

There are some disadvantages in using EDMS to manage all types including process validation, method validation, medical device validation such as:

Lack of mechanism for carrying out tests

Insufficient information for validation management

Lack of accelerator library

Absence of Automatic Traceability Matrix

GO!FIVE® Software Quality Testing – Acceleration platform for validations

GO!FIVE®, paperless validation software, arises from the need to adapt validation processes to the advancement of technology in production systems. A cloud-based Paperless System Validation platform to be used on computers, laptops, and mobile devices such as tablets, adding mobility and agility to validation and qualification projects. GO!FIVE®, Validation Lifecycle Management Software, is responsive, running on the most frequently used browsers such as Google Chrome, Edge, Firefox Mozilla and Safari, in complying with the requirements of GxP Pharma, cGMP guidelines, FDA 21 CFR Part 11, GAMP5®, GxP system validation, and GMP validation guidelines.

Saving time and money in system validation and equipment/utility qualification

The technological innovation behind the platform is changing the way validation projects have been conducted so far. In addition to proposing and enabling zero paper usage, GO!FIVE® the computer software validation, has features that will reduce a project completion time by 83%, much more efficient.

From preparing paper documents to online storage

All project documentation generated on GO!FIVE®, a GxP software, is stored online on a dedicated high performance server, with international certificates and qualified infrastructure, which confirm the commitment to high levels of security, confidentiality and service availability.

The platform comes with standard models for each document, according to GAMP5® and FDA CSV guidelines. It is also possible to customize the template for the client's visual identity and use automatic content tags for GO!FIVE®, a CSV validator, in order to insert the project information into the document. During the implementation, the GO!FIVE® electronic validation database is studied to adhere to the layout of the customer's default templates.

The software automation testing has an electronic signature and approval workflow that allows it to be configured, following serial models (approved one at a time) or parallel (all reviewers and/or approvers work at the same time, reducing total workflow time).

The design of this cloud system makes reviewing and approving documents remotely extremely flexible, which is a huge advantage when it comes to validation or qualification in companies with more than one site or working from home.

The platform suggests risk scenarios and tests according to the system to be validated. Several libraries of systems typically used in the Life Sciences industries are now available.

Extensive Technical Knowledge vs. Knowledge Library

Systems validation requires a multidisciplinary professional with extensive experience. It is important that one understands validation guides and the technology being validated to organize the information in a way that meets the expectations of auditors.

A lack of expertise can hinder the process, since the analyst is faced with systems that need to be validated, but in different ways. As an example of diversity, we can mention validating SAP® ERP (Enterprise Resource Planning) and a packaging machine - they are different contexts and control different processes, however both are critical to the final product.

With e-validation solution knowledge database (the library), the platform suggests risk scenarios and tests according to the system being validated. Several libraries of systems, typically used in the Life Sciences industries are already available, however, over time, this database library will grow according to available technologies. FIVE project consists of updating it throughout the QA software life cycle.

The existence of similar processes applied to different companies, and the large number of system validations of the same type, inspired FIVE's team to have the idea of creating the library. These are processes that have already been carried out previously and are constantly being carried out. In these cases, the knowledge database is also efficient in suggesting actions, preparing the environment, and discarding the need to start a validation project from scratch.

The library technical content is based on FIVE's experience counting on more than 1000 validation projects. In case that the Analyst is faced with a system in which he/she has never validated, the library will suggest requirements, risks, tests and mitigation actions (in case of medium and/or high risks), since it already contains this intelligence in its database.

Systems Validation Performed by Items

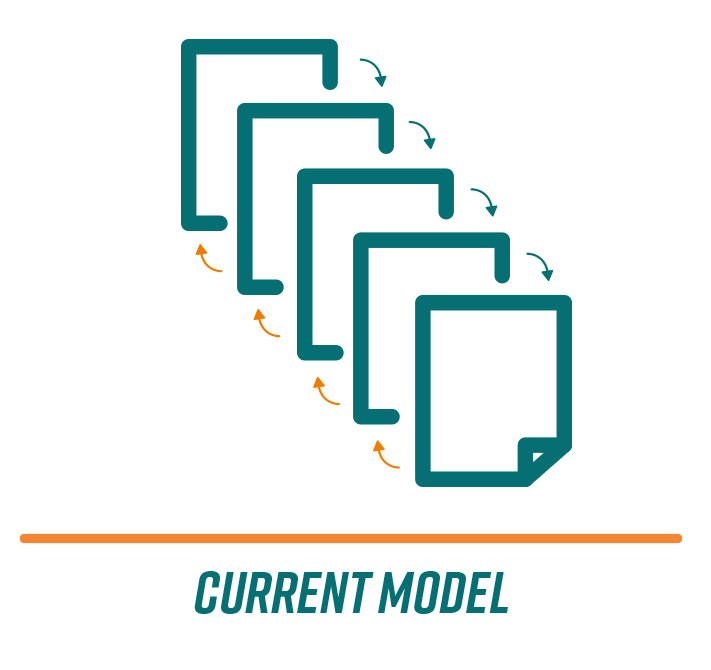

In classical validation, the analyst evaluates the entire system and generates at least one document for all requirements, one for all risks and another for tests (divided into IQ Installation Qualification, OQ Operational Qualification and PQ Performance Qualification).

In case of changes in the system or in the project, it is necessary to register the change and control the version of all approved documents.

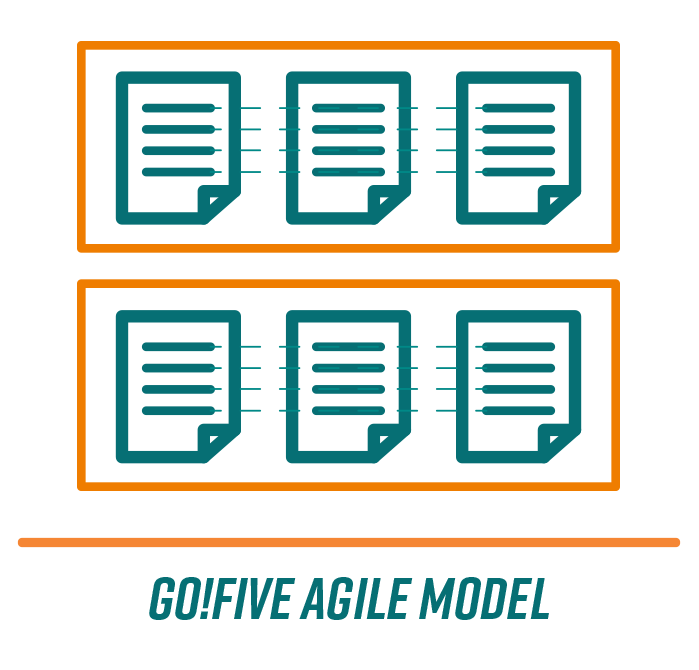

In e-validation software GO!FIVE®, you do not need to have all the system-wide risks and requirements approved before you start a test. The platform treats these documents as items and allows their review and approval to be performed independently.

There is also the possibility of one analyst creating the requirements, while the other creates tests, links the requirements, and sends them for review and approval by a third party. Everything in real time.

GO!FIVE® VLMS: An Agile Model

There is another advantage in case of change. Instead of generating a new version of the whole document, this “versioning” can be done in each affected item. The analyst performs a search on the Traceability Matrix of the item in question, edits, updates the relevant item, and then releases it for review and approval.

The Traceability Matrix is automatically generated by the system, which gathers the necessary information from User Requirements, Risk Analysis and Testing to generate the document.

When handling deliverables by items, GO!FIVE® speeds up processes in maintaining the system's validated state. In traditional validation, performed on paper, there is enormous difficulty in maintaining the paper, and reflecting the changes that have been made. Because the process is time consuming and requires the revision of most documents in the cycle. By allowing item validation, an update that could take days, is accomplished within only a few hours.

Privacy Policies

Each customer has a distinct tenant. So, they will have a different database section that one company will not be able to access the data from another company.

Data that is entered into the system is the customer’s responsibility.Our safety policies make it clear that FIVE is not allowed (and should not) access customer’s validation data to generate the knowledge database unless our employees are involved in those projects.

Learn more about GO!FIVE® Data Privacy Policy. GO!FIVE® Data Privacy Policy

The world is constantly changing

Currently, processes are evolving at a breakneck speed. Advancements such as Industry 4.0, Internet of Things, driverless vehicles, AI, blockchain, data integrity, computer algorithms, among several others, that were unknown only a few years ago, are now part of our daily lives.

GO!FIVE® is a validation solution that enables the industry to absorb new technologies with better performance and compliance.

This approach allows companies to look beyond cGMP guidelines with the advantage of today’s technologies, decreasing time spent and speeding time-to-market.

As of today, maintaining compliance has been a huge challenge. One can only imagine how continuing with the traditional validation paper method, and to keep it constantly updated, would be with all these new, burgeoning technologies.

Learn more

The platform has several other advantages over the classic concept of system validation and will contribute to reduce effort, cost, and time to validate a system while in compliance.

FIVE Validation has the answer you are looking for. Visit GO!FIVE® validation software site and get more information. GO!FIVE® site.

GAMP5® is a guide that has its intellectual rights reserved by ISPE™. Available for purchase at ispe.org